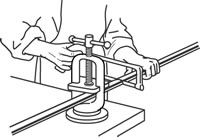

- 根据所需长度垂直切割管道,使得管道能够完全进入到阀门插口的肩部。刮除毛刺,进行锉磨。

Cut tube end square to exact length needed, so

that tube will enter valve socket all the way to the shoulder. Ream,

burr and file.

- 清理管道,清理长度比插入阀门插口的长度略长一些,然后清理阀门插口。可以采用钢丝刷,但是避免对金属过分清除。细砂布或金刚砂布可以采用,但和采用钢丝刷一样也要避免对金属过分清除。不建议采用钢丝棉。

Clean tube to a distance slightly more than what

will fit into the socket, and clean valve socket. Wire brushes may be

used, but avoid removing an excessive amount of metal. Fine sand cloth

or emery cloth may be used with the same precautions. Steel wool is

not recommended.

- 节俭地在管道和阀门插口上涂敷焊剂,使其十分均匀和细薄。要避免焊剂涂在为清理的表面上,特别是管道内侧。

Apply flux to tube and socket sparingly and with

a fairly thin consistency. Avoid flux on areas not cleaned, particularly

inside of tube.

- 组装准备铜焊的部件。如果容许焊剂部件出于竖立状态,则焊剂内的水分将会蒸发掉。干燥的焊剂会脱落,是暴露的金属表面被氧化。将管道插入插口内,直到插不进去为止来完成连接部分的组装。组装的部件应该有牢固的支撑,使得组装的部件在铜焊操作期间能够保持对直状态。建议在安装配置软阀座的截止阀时拆卸阀盖。

Assemble parts to be brazed. If fluxed parts are

allowed to stand, the water in the flux will evaporate. Dried flux is

liable to flake off, exposing metal surfaces to oxidation. Assembly

joint by inserting tube into socket hard against the stop. The assembly

should be firmly supported so that it will remain in alignment during

the brazing operation. Removal of bonnet is recommended when installing

globe valves with soft seats.

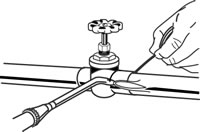

- 在要连接的部件上加热。最好采用氧炔焰加热方法。首先加热管道,从距离阀门2.5公分的位置开始加热。垂直环绕着管道上下来回短促扫着火焰。为了避免烧穿管道,火焰应该持续移动,不要停留在任何固定点上。

Apply heat to parts to be joined. The preferred

method is by oxyacetylene flame. Heat tube first, beginning one inch

from edge of valve. Sweep flame around tube in short strokes up and

down at right angles to run of tube. To avoid burning through tube,

the flame should be in continuous motion and not allowed to remain on

any one point.

在阀门的承插口底部进行加热。要均匀加热,从连接部到管道扫着火焰,直到连接件上的焊剂不会再发出吱吱声。要避免过度加热阀门。

Apply flame to valve at base of socket. Heat uniformly,

sweeping flame from fitting to tube until flux on fitting becomes quite.

Avoid excessive heating of valve. |

|

当管道和阀门上的焊剂都变成液状和透明时,则开始沿着连接轴向前后来会扫着火焰,保持连接部件的温度,特别是阀门承插口底部的温度。

When flux appears liquid and transparent on both

tube and valve, start sweeping flame back and forth along axis of joint

to maintain heat on parts to be joined, especially toward the base of

the valve socket.

- 将铜焊线或铜焊条按在插入阀门承插口的管道线上。在铜焊线(条)进入连接部位时,不要让火焰接触到铜焊线(条)。当合金被拉到连接部位时,前后来回移动火焰。当温度达到一定程度时,合金会很容易地流进管道外侧与阀门承插口之间的空隙中。连接完成后,将会看到连续的铜焊合金边缘。

Apply brazing wire or rod at point where tube

enters valve socket. Keep flame away from rod or wire at it is fed into

the joint. Move flame back and forth as alloy is drawn into joint. When

the proper temperature is reached, alloy will flow readily into space

between tube outer wall and valve socket. When joint is filled, a continuous

rim of brazing alloy will be visible.

螺纹

THREADING

砂砾,灰尘或任何在管道内累积的任何外在物质,都可能妨碍阀门的有效运行,并且严重损坏阀门的要害部件。要用空气或蒸汽全面彻底地清洗管道内部。

Grit, dirt or any foreign matter accumulated in

the pipe can hinder efficient valve operation and seriously damage vital

valve parts. Thoroughly clean pipe internally with air or steam.

在给管道攻牙(螺纹)时,要计算好管道螺纹的直径和长度,避免管道影响阀门的阀座和阀瓣。要全面彻底地清理螺纹连接端口,清除任何有害的钢铁残渣。在管道螺纹上涂敷螺纹油,但是不要在阀门螺纹上涂螺纹油。为了避免损坏阀瓣和阀座,不要让任何管道螺纹油流进阀体。

When threading pipe, gauge pipe threads for size

and length to avoid jamming pipe against seat and disc. Thoroughly clean

threaded end to remove any harmful steel or iron deposits. Apply pipe

dope sparingly on pipe threads, never on valve threads. Do not allow any

pipe dope into valve body in order to avoid damage to disc and seat.

在安装前,检查流进阀门的管道,使得阀门能够运转自如。在安装阀门前,要完全关闭阀门。在靠近管道的六边形上加上扳手,保证不会产生变形。在安装阀门后,要对管道加上支撑物,否则下垂的管道可能会使得阀门变形并造成故障。

Before installation, check line of flow through

valve so that valve will function properly. Close valve completely before

installation. Apply wrench to hex next to pipe and guard against possible

distortion. After installation of valve, support the pipe line; a sagging

pipe line can distort the valve and cause failure.

压缩

COMPRESSION

对于压缩端口连接,首先将压缩螺母移动到铜管上,然后装上套圈。在铜管上安装阀门,然后轻轻地把压缩螺母和套圈移到阀门上并进行啮合。不要使用管道螺纹油。旋紧螺母直到感受到阻力为止。然后再多旋转1/2圈。不要过分紧!

For compression end connection, first slide compression

nut onto copper tube, then slide on ferrule. Install the valve onto the

copper tube and gently slide compression nut and ferrule up to the valve

to engage. Do not use pipe dope. Tighten nut until resistance is felt.

Tighten additional 1/2 turn. DO NOT OVER TIGHTEN! |